Most Frequently Asked Question – 11th April 2024

I am shipping Dangerous Goods with Fedex, they have sent me a request for the transport category points. What does this mean?

Fedex are now requiring all consignors and freight forwarders to fully comply with ADR 5.4.1.1.(f) Note 1 and provide details of the load as it relates to the transport category and single or mixed load calculations. So what does Note 1 say “In the case of intended application of 1.1.3.6, the total quantity and calculated value of dangerous goods for each transport category shall be indicated on the transport document in accordance with 1.1.3.6.3. and 1.1.3.6.4.”

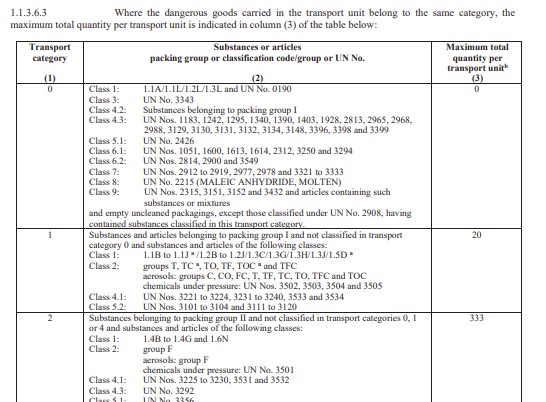

1.1.3.6.3 Exemption limit specified for each transport category. The table indicates the maximum total quantity (either litres or kilos) that may be carried in a vehicle without requiring an ADR driver and the display of orange coloured plate to be present on the vehicle.

As Fedex are collecting multiple shipments across their network, it makes sense that they are requesting this type of informtion. In fact we always talk about how the express parcel system has been operating aand if they are within the limits of ADR when doing multiple collections. It has always been a bit of an unknown. So this is how it works, you will need to reference Section 1.1.3.6.4.

When dangerous goods of different transport categories are carried in the same transport unit the sum of the dangerous item shoulld not exceed 1000. When the collections go over this limit an ADR driver and orange coloured plates are required.

| Transport Category | Calculation Required |

| Transport Category 1 | Multiple the amount being shipped by 50 Note: if the UN # of Class / Division is specified in column 2 of the table in 1.1.3.6.3 then the amount should be multipled by 20 |

| Transport Category 2 | Multiple the amount being shipped by 3 |

| Transport Catgeory 3 | Use the exact amount that is being shipped without any multiplications |

| Transport Category 4 | Does not need to be considered as unlimited quantities can be shipped. |

If I was to transport 50 kilos of Lithium Batteries. The transport category is 2. I can then determine my transport category points as 50 kilos x 3 = 150 transport category points. This information should be added to my dangerous goods transport document (DGN)

If I was to transport 20 litres of UN1824 Sodium Hydroxide Solution PG III, The transport category is 3. I can then determine my transport category points as 20. This information should be added to my dangerous goods transport document (DGN)

If I was transporting both items on the same dangerous goods transport document, I would have to add them both together 150 + 20 = 170 transport category points. The total should be documented in the dangerous goods transport document.

If we comply with Fedex’s request it will help the driver ensure that during their day of collecting packages they are NOT going over the total limit of 1000 points. They can make an informed decisions on if they are able to make further dangerous goods collections. Most importantly it helps keep the driver and us on the roads safe. Which of course we all support.

If you have any questions on your specific products and the transport category points, please do not hesitate to contact the team at Logicom Hub Ltd Tel 0330 912 5041 Email: [email protected]